How is beer production different to wine production?SOLUTIONS PROVIDER

Many assume that wine and beer-making follow a similar process. The truth is whilst the processes have many similarities, there are a number of core differences that require differing pieces of equipment and follow slightly different processes. We discuss the key differences between beer and wine production below.

Kegged Cocktails

Premade cocktails can now be found on tap at many on premise venues. We discuss why kegging cocktails is an innovative concept more venues should adopt.

What is CO2 used for in beverage packaging?

C02 is a very common ingredient in many beverage products, both alcoholic and non-alcoholic, but what is it actually used for and what are some examples of C02 beverage products? We discuss why C02 is used in beverage products in this blog.

Can sizes simplified

A quick glance at any drink isle in the supermarket or liquor store will demonstrate the wide variety of can sizes that are utilised in the market. We simplify the various can sizes and explain the difference between the various can sizes and formats.

How to Start a Private Label Wine Business From Square One

Every thought about starting your own private label wine business? Starting a private label wine business from square one is easier than you may think.

What products can be kegged?

A vast range of beverage products can be kegged. Keg’s are largely used by pubs, bars and restaurants (also referred to an on premise venue) whilst a small amount are also utilised by individuals in at home bars. We discuss below the types of alcoholic beverages that can be kegged.

What are the regulations surrounding chemical storage in Australia?

In Australia there are a numerous requirements for chemical storage and the treatment of dangerous goods. Here at IDL we have on site a number of dangerous goods and chemical products that are required for our wine, cider and RTD beverage creation purposes, as well as our packaging services.

How do lot codes work?

Lot codes are a mandatory requirement under the Food Standards Code in Australia. Lot numbers help manufacturers trace every item produce from their facility. This is particularly important if the unfortunate situation of a produce recall or withdrawal arises.

How does a glass bottling line work?

Glass bottling lines are complex pieces of machinery with various components that all must be operating effectively to successfully complete a glass bottling beverage production run. We outline below the process flow which occurs at our glass bottling beverage production facility.

Canning wine and bottling wine. How do they differ?

Canning wine is a trend that has gathered momentum in recent years. Common varieties that are canned are sparkling, rose, Moscato, Pinot Grigio and Sauvignon Blanc. In this article we discuss the differences in canning wines compared to bottling wines.

What goes into glass bottling packaging runs?

Glass bottling packaging runs may appear seamless and simple when witnessing the packaging lines operate. However, there’s an incredible amount of background work that goes into facilitating a glass bottling packaging run. We’ve outlined below all the requirements that are organised before and during a glass bottling packaging run

Expected beverage trends 2023

Each day, week, month and year consumer preferences are evolving and changing, and brands are challenged to keep up with these changing consumer preferences. We outline the trends we anticipate will appear in the beverage sector for 2023 here in Australia.

Kegging Equipment: What is needed to properly keg Cider?

Quality kegging equipment is vital to ensure the product inside the keg has its quality maintained from the point of packaging until the point of sale. At IDL, our keg line is manufactured by Comac and is an automatic keg line that fills 20L and 50L kegs. There are several incredibly important elements of any quality piece of kegging equipment.

Cider keg design and functionality: Why a proper set up is important

A proper keg line design is imperative to ensure the environment and product are sterile to ensure the viability of the product. Learn more about out top tips for a proper keg line design.

Tips and tricks when canning rtd products

When canning rtd beverages there are a number of things to carefully consider and ensure are effectively being done to ensure the viability of the product. Learn more about things to consider about canning rtd beverages

The do's and dont's of rtd manufacturing

When it comes to ready-to-drink (rtd) manufacturing there are many moving parts to the process which must be meticulously managed to ensure the final product is as it should be. From ingredients to following the recipe, sending the product to package, all steps are vital to ensure the product is produced to standard.

Canned cocktails are all the hype

Every quality liquor store now has a vast selection of canned cocktails on their shelves. Crafted to taste as good as your local bartenders creation, canned cocktails are tipped to be a hot item in Summer 2023

Manufacturing of Wine: How to Simplify

As a full-scale beverage manufacturing company, we have all the technology available and know all the industry lingo to explain the technical processes of manufacturing wine. However, the manufacturing of wine process can be simplified. We’ve simplified the manufacturing of wine process so everyone knows what goes on.

How does new beverage product development work?

New product beverage development is a creative process that centres around crafting new products that satisfy a product brief. A talented food and beverage technologist is responsible for the new product development process and has the desired skills in pairing flavours to create new products. Learn more about what goes on behind the scenes before a new beverage product is launched.

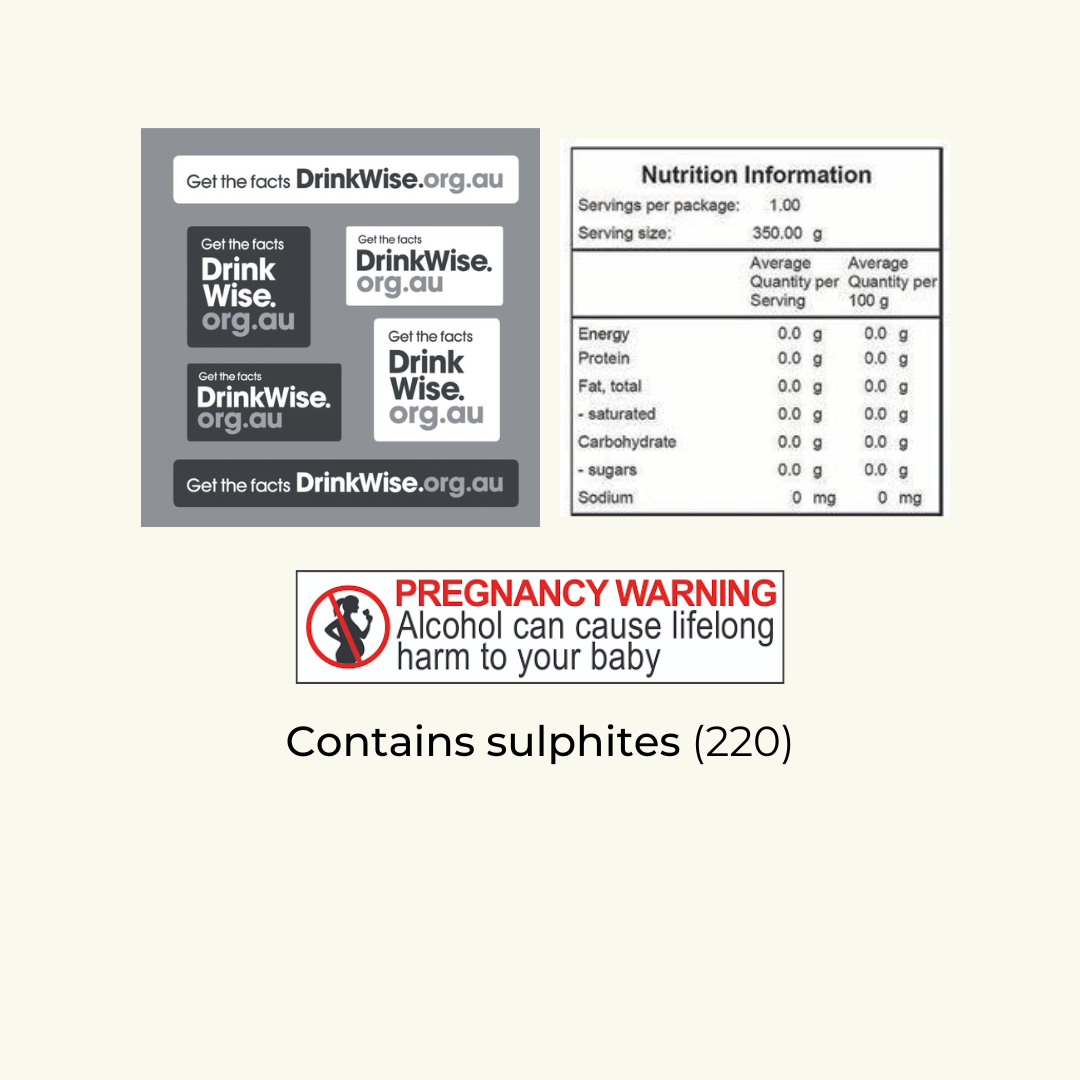

The importance of adhering to alcohol labelling mandatories

In the alcoholic beverage industry, there are a number of alcohol label mandatories that are required to be on each individual unit and outer packaging of products. Compliance laws are updated often and manufacturers need to stay on top of current requirements. Below we discuss the current requirements for alcoholic beverages.