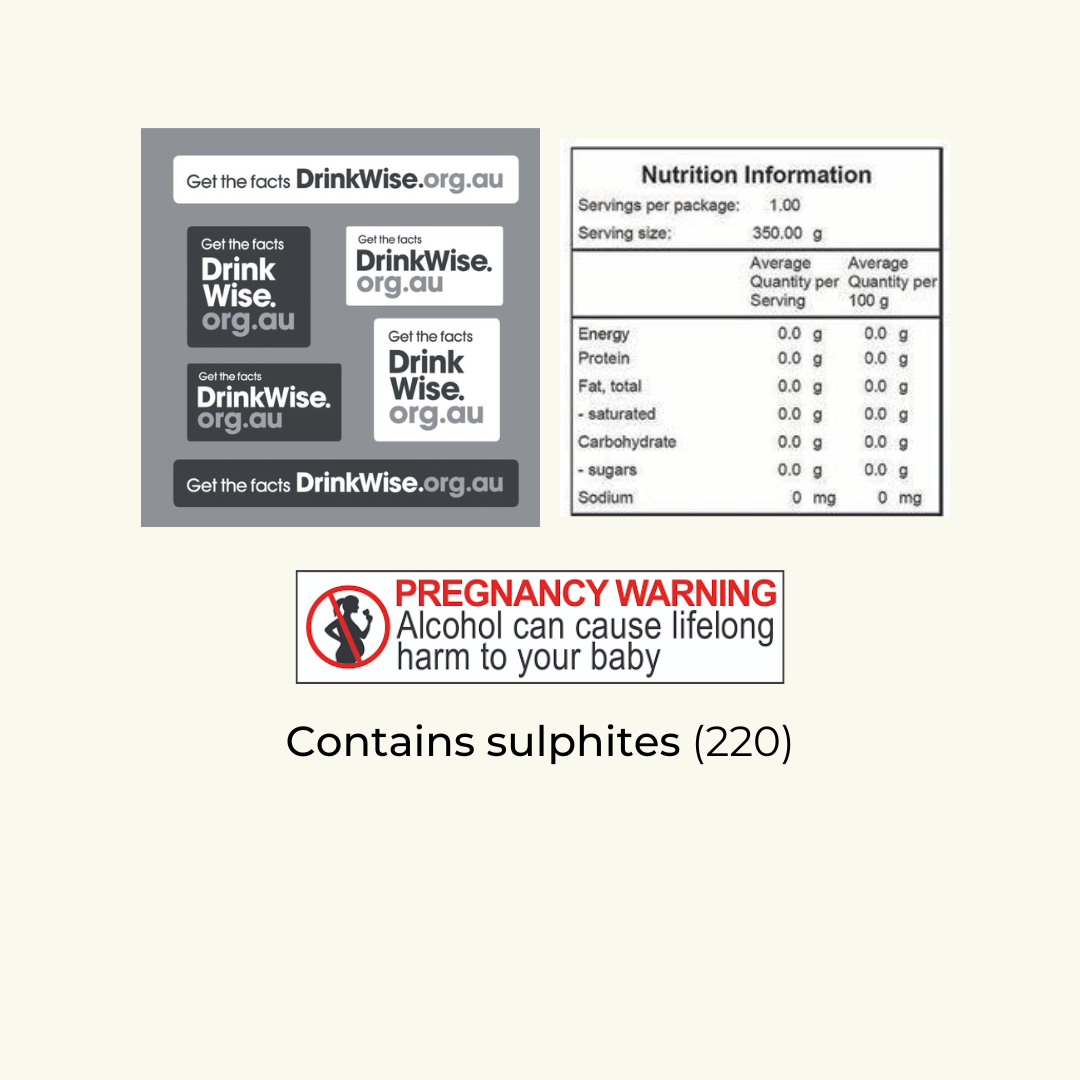

The importance of adhering to alcohol labelling mandatories

In the alcoholic beverage industry, there are a number of alcohol label mandatories that are required to be on each individual unit and outer packaging of products. Compliance laws are updated often and manufacturers need to stay on top of current requirements. Below we discuss the current requirements for alcoholic beverages.

No and low alcohol trends – is it a thing?

There is an abundance of conversations being generated regarding non alcoholic or low-alcohol beverage products. There is a growing consumer preference for these sort of beverages, but just how big is the movement?

Benefits of engaging a contract canning company

A contract canning company is a company that fills cans with beverages, and offers this service to other companies. The contract canning company is responsible for canning the product whilst the customer will be responsible for label development and design, and more than likely the recipe development too – however some contract canning companies are capable of this. Contract canning is an effective solution for many beverage companies.

A guide to Australia's hottest ready to drink beverages

Aussie’s enjoy a diverse mix of beverages from wine to cider to ready-to-drink beverages and everything in between. We outline the hottest trends currently on the market, and what trends we predict for the future.

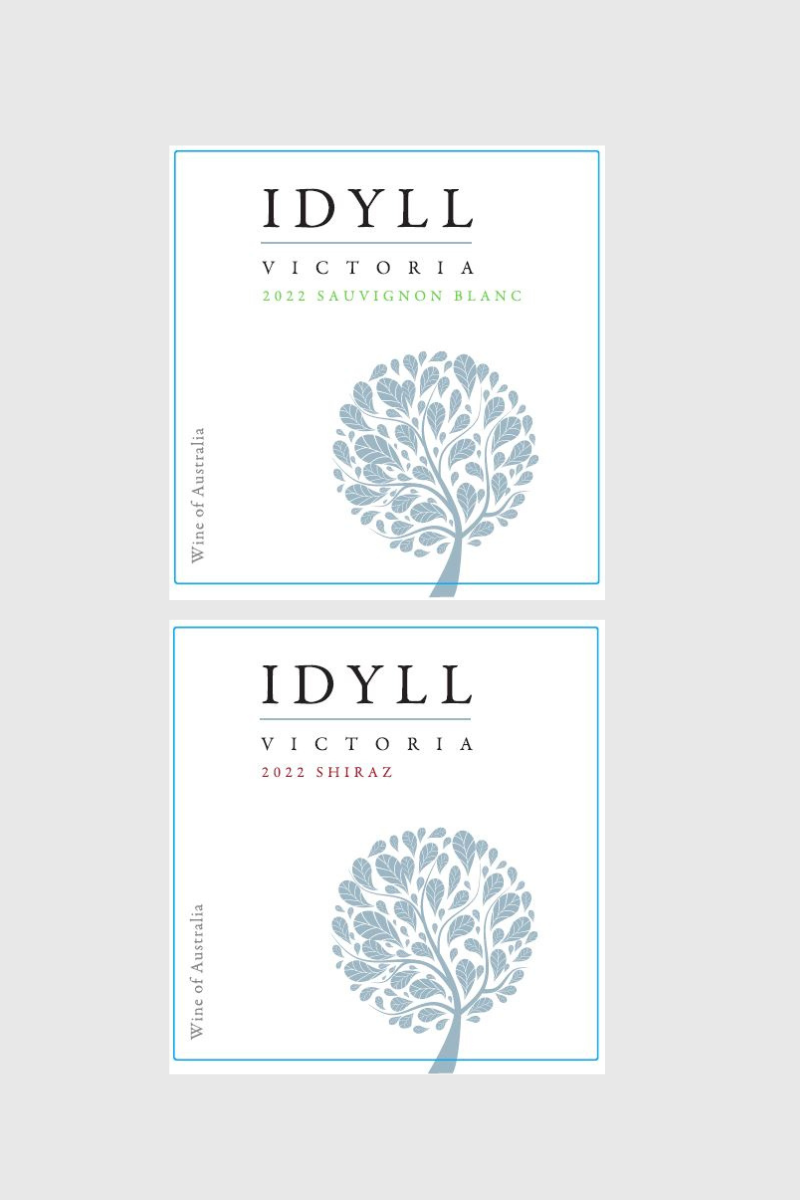

Wine Label Design & Printing: 6 Attention Grabbing Tips

Having a well crafted and attention grabbing wine label design is imperative to stand out amongst the clutter on the shelf.

What is Velcorin® dosing and why is it needed?

Velcorin® is a beverage preservative that extends the shelf life of products by preventing the growth of yeast, mould and other microbiological contaminations. It is a cold sterilisation agent for beverages.

Label your own wines: Why you should

Many brands that operate purely by designing their own labels and partnering with a private label manufacturer to create their product. Whilst they do have some control over the product output, their core competency lays in labelling their own wine. This is known, in the industry as Private Label Wines.

What is contract bottling and how does it work?

Contract Bottling is when one company hires another to bottle their beverage product for them. The company who bottles the product for the customer are known as a contract packer or co-packer.

The simplest ready-to-drink products you can make

Great-tasting quality beverages don’t always mean a complex recipe and an array of exotic ingredients. Take a look at the most popular products and brands on the shelves currently and you may realise just how simple their recipe actually is. Learn more about what we believe are the most simple ready to drink products to make.

Language of Bottling, Kegging & Canning - a glossary of terms

There are some unique terms that you’ll come across when you start you journey in beverage production. Learn about some of the most common industry terms and what they mean.

How to choose a contract bottler

A contract bottler is a company that packages your beverage product into your desired packaging format. They are responsible for the final sign-off on the products liquid before packaging it into the desired bottle size, colour and shape alongside any labelling and boxing requirements. When trusting a third party to package your product, it is important that you are satisfied with the company’s operations. Here are the things to check for:

Bottling Wine With Corks: Pros and Cons

Many wine packaging decisions are based on the benefits of each raw material, how the packaging line is capable of packaging wine and what the producer thinks will look best. We discuss the benefits and downsides of using traditional corks when bottling wine.

Ready to Drink Canning Line: How It Works

A ready to drink canning line is a complex piece of equipment that is relatively simple to operate. Once you understand how a ready to drink canning line works, you have the opportunity to package an array of beverages on the canning line in a range of sizes and shapes.

What is a ready to drink product?

A ready to drink product is a drink packaged in a prepared form for immediate consumption. Ready to drink (RTD) products can be both alcoholic and non-alcoholic. There is a growing trend in alcoholic RTD products with a new generation of drinkers. RTD drinks can be packaged in an aluminium can, glass bottle, aluminium bottle or even kegs.

Kegging Basics Explained for New Brewers

Kegging can be quite a complex process to ensure you’re adhering to all quality standards to safeguard the viability of your product. There are a number of kegging basics that you should know before you start kegging your brews. We’ve outlined the must know kegging basics for new brewers, getting you ready for your first batch of kegging.

Bottling Beverages From Juice to Ginger Beer and Everything in Between

Here at Idyll we produce and package a range of juice-based products, as well as Ginger Beer and read-to-drink spirit products. Bottling beverages is a complex process that includes crushing fruit, fermenting, perfecting the recipe and packaging into the desired packaging format.

Pros and Cons of Private Label Wines

Private label wines are an effective way to enter the wine market when you’re not an expert in Winemaking practices and lack connections to source quality wines and package products. Establishing a brand whilst utilising a private label wine manufacturer enables a company to excel at branding, marketing and distribution.

Scale your beverage business with outsourced contract packing

You’ve mastered your recipe, you think there’s a gap in the market, you’ve got a stockist, but how are you going to get your product packaged and on the market? This is where contract packing is incredibly useful as a contract packer comes in to really bring your product to life.

Bottling Sparkling Wine: Here’s What You Should Know

In order to ensure your product is packaged to the optimal standard we share some key information to make bottling sparkling wines a success.

Craft Cider Canning: In House or Contract Out?

When you’re starting a new cider brand or company, questions around whether or not you should package the product yourself or contract out to a beverage manufacturer are often at the forefront of business decisions. There are benefits and limitations to each option, with the ultimate ideal solution depending on your business model and set up.